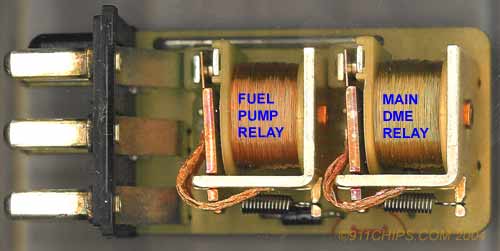

Contained

within the relay are actually two relays which

operate in sequence of the other. When starting

the car, power is supplied to the main DME relay,

powering the DME computer. As long as the DME

sees the engine turning a minimum of 200 rpms,

it switches on the fuel pump relay, powering the

fuel pump and allowing the car to start and run.

This is designed as a saftey precaution, shutting

off the fuel pump in the event of an accident

where the fuel system ruptured. Pictured below

is the interior of a failing DME relay. This relay,

installed as a replacement six years ago, has

already begun failing. Note the heat induced discoloration

of the red enamel wire coating of the main DME

coil compared to those of the fuel pump. Shown

in it's actual position mounted on the car's floorboard,

note the horizontal mounting position of the heavy

copper relays onto the vertically positioned circuit

board. Heat, along with the vibration and shock

that the heavy relays place on the support joints

all contribute to solder joint failure.

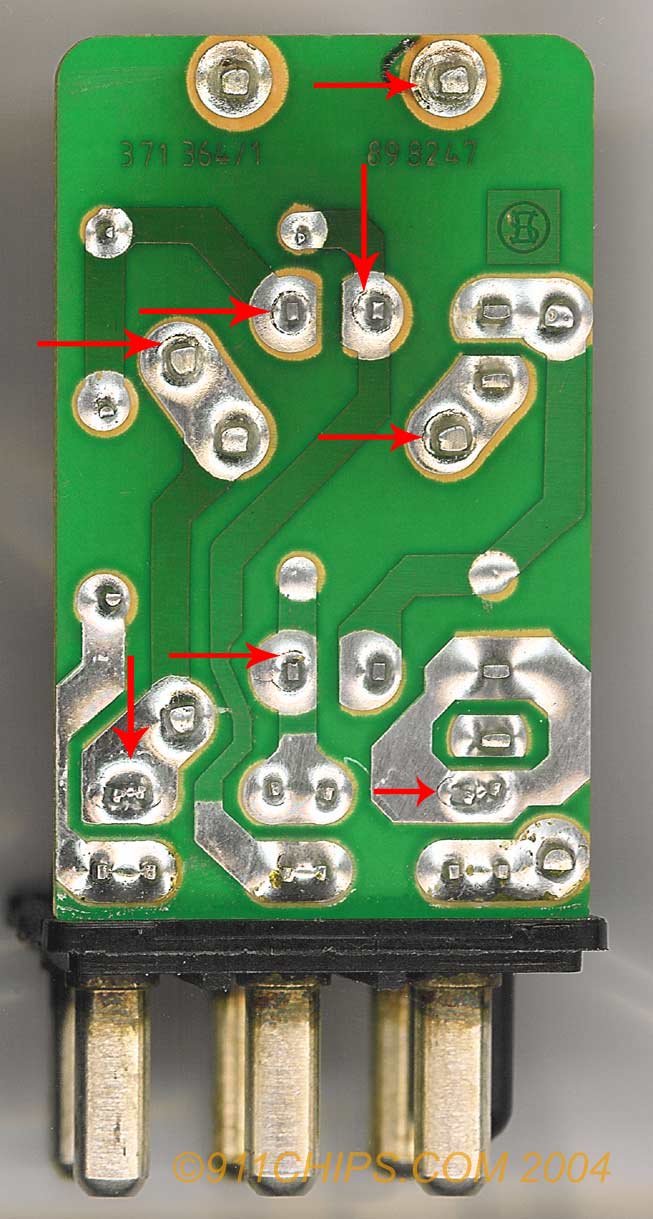

DME

Relay - Cracked Solder Joints

Examining

the back of the board, we can see that most of

the failed joints are due to overheated solder

joints. In addition, we can see a minimum amount

of solder at each joint, most likely for production

cost savings. This leaves less material for heat

dissapation and structural strength. A few are

on their way to complete separation, while most

are completely separated. Vibration, movement,

and heat from thermal cycling all cause intermittent

contact, resulting in sporadic instances of start

and no start conditions. The simplest solution

is to always carry a spare, resoldering and reflowing

the joints in your old or new one with an adequate

amount of solder, two to three times the original

volume, providing better heat dissipation and

virtually eliminating the likelihood of future

failure. Click image for a closer view.